Wall Colmonoy is pleased to announce they will be exhibiting at International Thermal Spray Conference (ITSC) 2024 Booth 428 in Milan Italy, from April 29 to May 1, 2024.

As a leading manufacturer of nickel and cobalt powders, Wall Colmonoy Limited (UK) will be promoting their range of new and existing Colmonoy® (nickel-based) and Wallex® (cobalt-based) hardfacing alloys. Supplied for a variety of proven thermal spraying and welding techniques for Spray & Fuse, Laser Cladding, Plasma Transferred Arc (PTA), HVOF and Plasma Spray.

Wall Colmonoy Limited (UK) also provides high performance wear-resistant coatings for both repairs and new parts. Wall Colmonoy Limited (UK) can apply hardfacing materials, such as our proprietary Colmonoy® and Wallex® alloys, carbides and blended coatings including tungsten carbide for superior wear or abrasion resistance. Application methods are by Spraywelder™ System (Flamespray), Fusewelder™ Torch (Powder Welding), HVOF, PTA, and Laser Cladding.

Wall Colmonoy’s hardfacing alloys and coatings address wear-related challenges by extending the service life of parts in industries such as:

- Glass Container

- Oil & Gas

- Rubber & Plastics

- Waste to Energy/ Biomass

- Steel

- Mining

- Pumps

- Pulp & Paper

- Agriculture

Register here for a free ITSC 2024 exhibition hall pass!

Contact us to find out more or discuss your hardfacing and thermal spray needs

Hard Surfacing Equipment

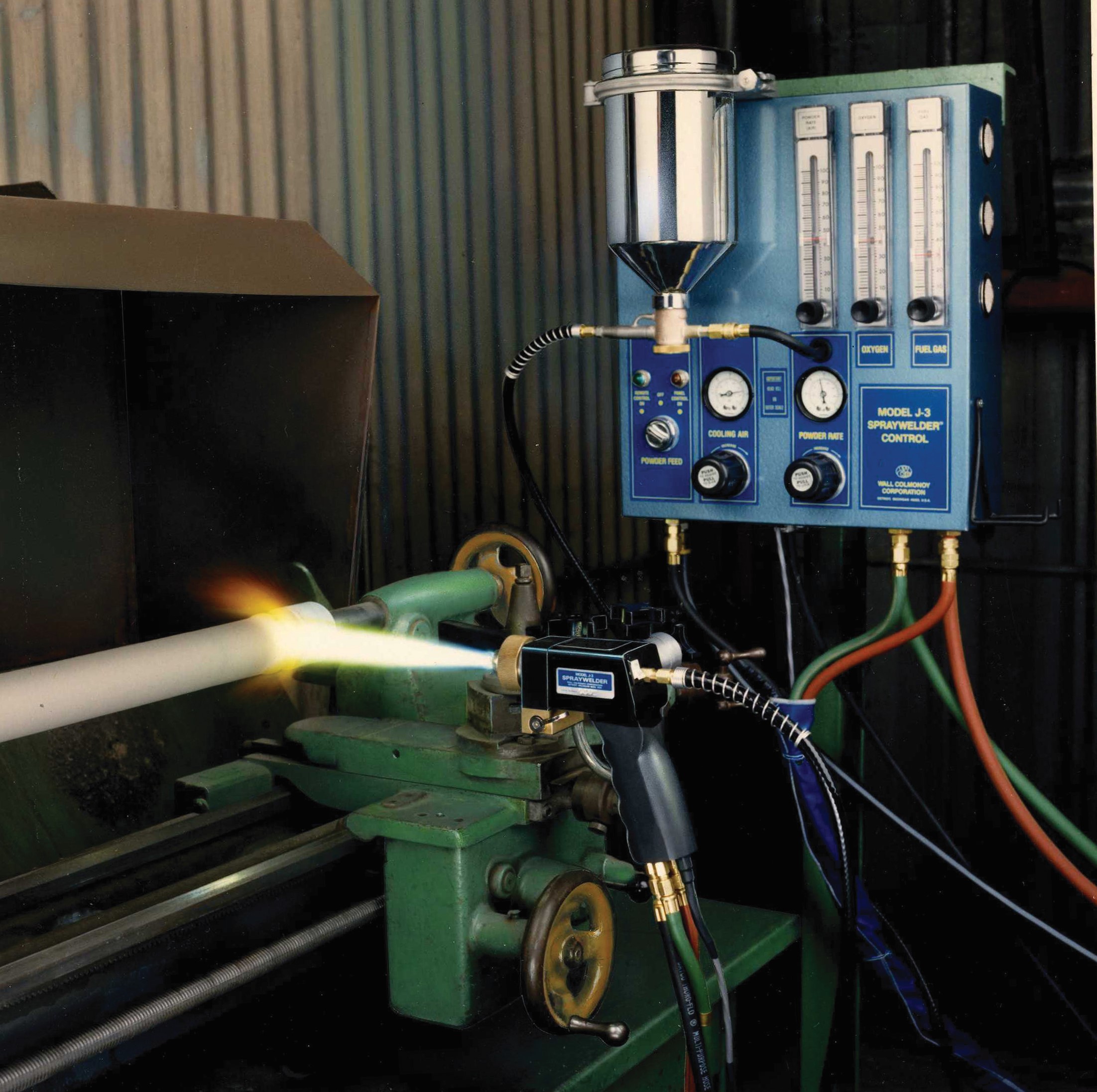

The Spraywelder™ System

The Spraywelder™ System is the industry's leading process to rebuild surfaces and provide wear protection. The Model J-3 is the culmination of more than 65 years of technical innovation following the invention of our first thermal spray gun. Designed to produce a consistent coating for circular parts, the Spraywelder™ System offers tight spray pattern and high spray rates to produce dense, low porosity overlays –ideal for seal areas, shafts on motors, fans, and glass industry parts such as plungers and plugs.

The Sprayweld™ process offers numerous advantages that favour its many applications:

- Adjustable equipment settings to suit your application

- High powder deposition efficiency minimises powder loss

- Close tolerance control

- Reduced finishing time

- Wide range of system alloys

Model J-3 Spraywelder™ System

Model J-3 Spraywelder™ System

Download our brochure on The Spraywelder™ System

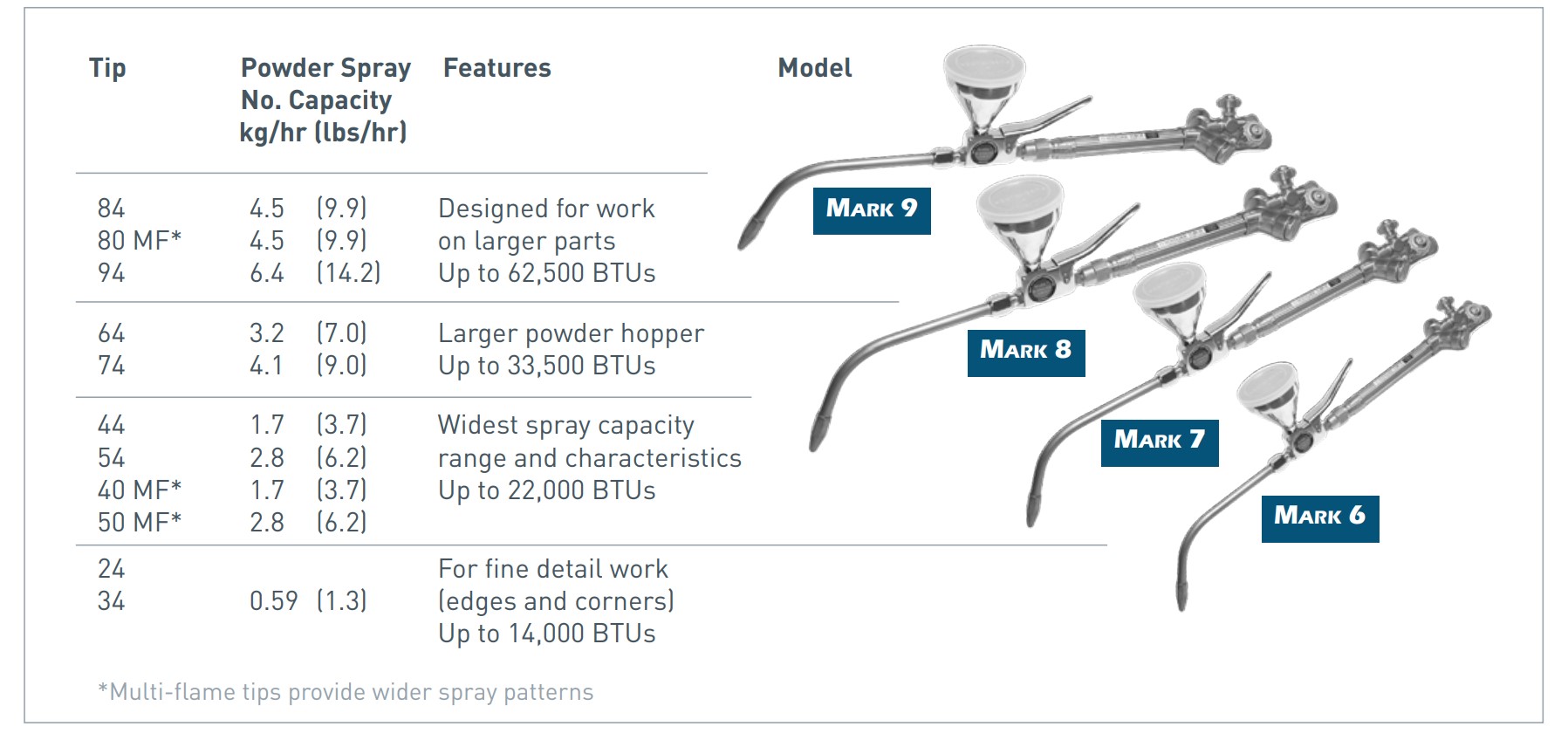

The Fusewelder™ Torch

The Fusewelder™ Torch is a special oxy-acetylene torch which preheats the base metal, sprays powdered alloy and fuses deposits to the workpiece – all with one integrated unit.

The range is made up of four models, each with a different powder spray capability:

The Mark 9 model has a superior powder deposition rate with a powder spray rate of between 4.5 kg/hr and 6.4 kg/hr (9.9 - 14.2 lbs/hr)

The 80MF is a unique design for this type of torch due to its 3-hole multi-flame nozzle, making it ideal for coating large areas quickly and with ease.

For difficult to reach areas, nozzle extensions can be made in three different lengths:

- 177.8mm

- 254mm

- 457.2mm

These can be applied individually or joined together to achieve longer lengths.

Durable and versatile, Wall Colmonoy’s Fuseweld™ process is an easy, trouble-free operation that achieves superior results.

Download our brochure on The Fusewelder™ Torch

Register here for a free ITSC 2024 exhibition hall pass!

To find out more or discuss your hardfacing and thermal spray needs, please don't hesitate to contact us.