Colmonoy® 7541-55F, with 55% tungsten carbide is an ideal protective coating for the most severe abrasive conditions. It is typically used on equipment such as stabilisers, steering pads, and sleeves. It is particularly ideal as a protective coating for steering pads. In this application, the steering pad is subject to extreme wear conditions as it is made to press against the side wall to deflect the direction of the drill chain. Colmonoy® 7541-55F contains cast and crushed tungsten carbide particles with average hardness values around 2200HV whilst the average deposit hardness ranges between 50-60HRC.

In addition, Colmonoy® 7541-55F uses Colmonoy® 25F as a dust coat, ensuring the surface is not subject to oxidation. Once the dust coat is applied and preheat complete, inserts are cemented in place using Colmonoy® 7541-55F. This alloy is designed for extra heavy-duty service conditions, such as drilling applications where the geo-strata is particularly abrasive. Colmonoy® 25F and Colmonoy® 7541-55F are suitable for standard steel and non-mag equipment.

This alloy can also be applied as a tough coating in applications where tungsten carbide inserts are not required or in the most severe, arduous applications where tungsten carbide inserts plus carbide bearing powder work together. Designed to be easy to apply and highly abrasion resistant, Colmonoy® 7541-55 is typically applied with a thickness of 3 mm.

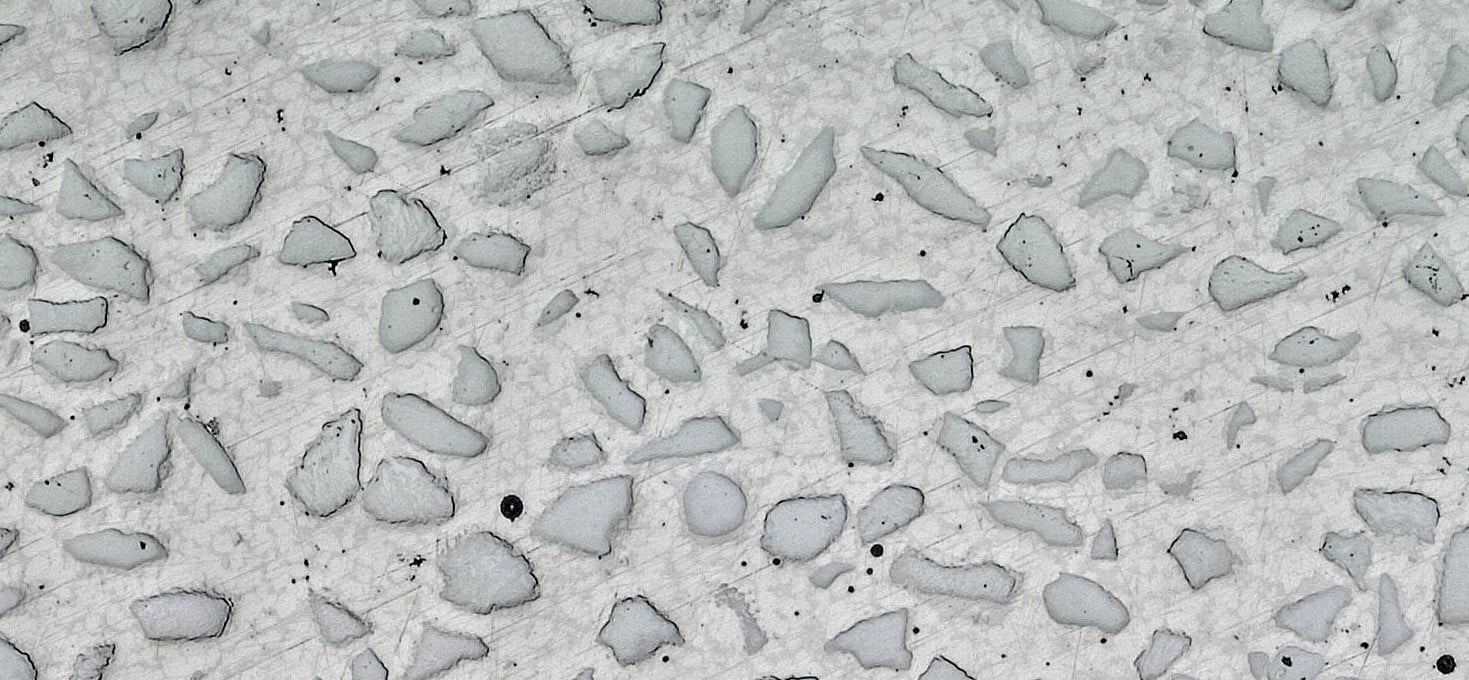

Colmonoy® 7541-55 with no inserts

Colmonoy® 7541-55 with no inserts

Colmonoy® 7541-55 with insert to left

Colmonoy® 7541-55 with insert to left

More about Oil & Gas Alloys:

Colmonoy News Extending Useful Life of Downhole Tools

Have a question?