Wall Colmonoy supports the Steel Industry with as cast and fully machined Precision Components, designed to optimise against wear, corrosion, abrasion, and heat resistant properties.

Left-to-right: Sand Cast Roll End Bush, Sand Cast Guide Bush, Sand Cast Skid Bar.

Our Precision Components team offers an integrated approach of cast engineering and manufacturer to fully machined components, to increase lifetime of parts, reduce downtime and costs for steelworks across UK, Europe, Asia and the United States.

Wall Colmonoy pours Colmonoy® (nickel-based), Wallex® (cobalt-based) and customer-specific cast alloys using the casting methods of Sand, Investment, and Centrifugal or Hot Isostatic Pressing (HIP). Our engineers can advise optimum alloy selection and process to suit specific needs.

“Overall Equipment Effectiveness (OEE) is imperative within the Steel industry and is precisely where we support. We have long-standing relationships in the industry, and a proven track record of providing first-class solutions,” explains Michael Shreeve, Business Development Manager.

Wall Colmonoy realizes the importance of working in collaboration with our customers to further understand needs and help increase the lifespan of components for Steel manufacture – reducing downtime and costs.

“Part of our mission and values is to collaborate with our customers to find innovative solutions. Our objective is to ensure longevity and improved successes for our customers which includes increased lifespan, reduced downtime and operational expense. Wall Colmonoy has been around over 80 years so we are here for the long-term with continued investment in our people and processes.”

Wall Colmonoy's castings are processed through applied technologies such as automation, collaborative robots, data analytics - embracing Industry 4.0. Quality castings are assured through advanced laser measurement techniques. For Rapid Prototyping, we implement 3-D printed investment patterns and tooling, reducing the necessity for tooling on small batches and product qualification.

As Cast and Finish Machined Components for Steel Industry

Re-heat Furnaces, Hot & Cold Rolling, Galvanising Lines and Continuous Casting

| Component | Alloy | State | Department |

| Kidney Folks | Wallex® 250 | As Cast | Re-heat Furnaces |

| Skid Rails | Wallex® 250 | As Cast | Re-heat Furnaces / Hot Rolling |

| Buttons | Colmonoy® Cast 48, Wallex® 4, 6 | As Cast | Re-heat Furnaces / Hot Rolling |

| Long Skids | Wallex® 250 | Finish Machined | Re-heat Furnaces |

| Roll End Bushes | Wallex® 4, 6, 12, 21, 180 | Finish Machined | Galvanising Lines / Cold Rolling |

| Bearings | Wallex® 6 | Finish Machined | Galvanising Lines / Cold Rolling |

| Bush | Wallex® 4, 6, 180 | Finish Machined | Galvanising Lines / Cold Rolling |

| Scrolled Bush | Wallex® 6 | Finish Machined | Galvanising Lines / Cold Rolling |

| Spherical Bush | Wallex® 4, 6 | Finish Machined | Galvanising Lines / Cold Rolling |

| Eccentric Bush | Wallex® 6 | Finish Machined | Galvanising Lines / Cold Rolling |

| Arm Roll | Wallex® 6 | Finish Machined | Galvanising Lines / Cold Rolling |

| Thrust Pads | Wallex® 6 | Finish Machined | Galvanising Lines / Cold Rolling |

| Bush Segment | Wallex® 4, 6, 180 | Finish Machined | Galvanising Lines / Cold Rolling |

| Retaining Ring | Wallex® 6 | Finish Machined | Galvanising Lines / Cold Rolling |

| Burrmasher Rolls | Wallex® 6 | Finish Machined | Cold Rolling |

| Cropping Knives | Wallex® 21 | Finish Machined | Continuous Casting |

Application Roll End Bush |

|

Application Scrolled Bush Application Scrolled BushProduct Wallex® 6 Casting Method Sand Cast / Finish Machined |

|

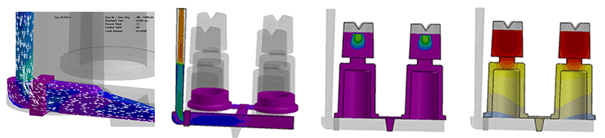

Engineering quality into our Products at the first stages through Simulation, to increase right first time, throughput and customer satisfaction.

Engineering quality into our Products at the first stages through Simulation, to increase right first time, throughput and customer satisfaction.

For technical consultation on your Steel application, contact us.

CONTACT

Wall Colmonoy Limited

Darren House

Alloy Industrial Estate

Pontardawe, Swansea,

Wales (U.K.) SA8 4HL

E: componentsales@wallcolmonoy.co.uk

T: +44 (0) 1792 860647

Application Guide Bush

Application Guide Bush  Application Bearing Bush

Application Bearing Bush