In severe service applications, like in Oil & Gas or Chemical Processing, control valves’ multi-path trims manage high pressure drops, high temperatures, and prevent cavitation during operation. The trim diverts fluid into many tiny pathways, which can dissipate the pressure and prevent wear.

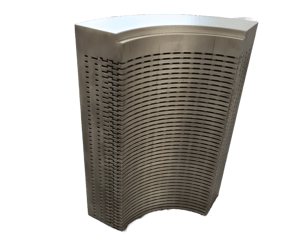

In this example, a multipath control valve trim is fully assembled and vacuum brazed with Nicrobraz® 135, a high temperature nickel-based brazing alloy, at our facility in Pontardawe, UK. The valve trims are manufactured by stacking and joining laser cut discs together. Nicrobraz® 135 was applied via the Nicrospray™ System in combination with Nicrobraz® Cement, a liquid plastic used for mixing with brazing filler metal powder to ensure adhesion to the base metal during the brazing process. The NicroSpray™ System is used for fast, smooth, uniform, and specifically here, for a highly scalable precision method of brazing filler metal application.

Nicrobraz® 135 was used to join the stacks due to its relatively low brazing temperature range of 1010-1175°C (1850-2150°F), excellent flow and wetting properties, high joint strength and ductility, and improved machinability during further processing of brazed stacks.

The use of vacuum brazing allows for the assembly of complex flow channel technology in different materials such as Inconel, stainless steels and nickel alloys. This assembly and braze process creates a high strength joint strong enough to withstand the extreme pressure of the fluid as it makes its way through the control valve trim.

|

Disc for a multi-path Control Valve Trim sprayed Nicrobraz® 135 and Nicrobraz® Cement via NicroSpray™ System |

Brazed and Assembled Cross section of the Control Valve Trim |

At our Brazing Engineering Centres, located in Pontardawe, Wales and Cincinnati, Ohio, we bring together decades of practical experience of brazing. Whether it’s designing a brazing joint, developing a new brazing filler metal, contract vacuum brazing services or total manufacture to print, Wall Colmonoy is a world-leading destination for brazing expertise.

Talk to us about your brazing project: