Wall Colmonoy returns for a sixth year at the Laser Additive Manufacturing Workshop, Conference and Exhibition.

Our Sales & Technical Team will be on-hand at Booth #32 to discuss your laser cladding and additive manufacturing applications.

To contact our team attending the tradeshow, David Lopez, Sales Engineer, and Mike Weinstein, Technical Services Manager, click here:

COLMONOY® and WALLEX™ hardfacing and wear-resistant powders and wires, dedicated to Laser Cladding, are used for the protection and renovation of critical industrial components.

Some industries and applications include:

- Power Generation - Boiler Tubes, Panels, Industrial Fan Blades, Coal Nozzles, Soot Blower Lances...

- Steel - Continuous Cast Rolls, Transporter Rolls...

- Oil & Gas - Drill Stabilizers, Valves, Rods, Couplings...

To download our Laser Cladding Technical Data Sheet, click here:

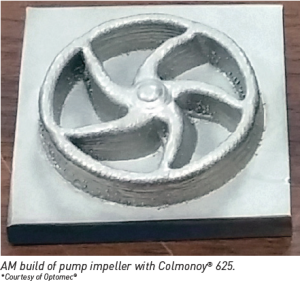

Wall Colmonoy is capable of producing Colmonoy® (nickel) and Wallex™(cobalt) alloys for additive manufacturing, also known as 3D printing. The alloys are induction melted and gas-atomized to meet current industrial needs utilizing either powder bed or blown powder additive techniques.

Wall Colmonoy's powders can be customized to work on major additive manufacturing techniques such as:

- Laser Engineered Net Shapes (LENS)

- Electron Beam Melting (EBM)

- Direct Metal Laser Sintering (DMLS)

- Selective Laser Sintering (SLS)

- Direct Metal Deposition (DMD)

For more information on Additive Manufacturing, contact us:

LAM 2016 Registration Discount

Download registration form with code WALLCOLMONOY: