Colmonoy® Laser Clad Coatings Withstand Abrasive Wear in Steel Manufacture

Colmonoy® 7331-60 has improved the service life of transfer rolls used in the steel industry by 3 times over uncoated rolls.

Colmonoy® 7331-60 is a wear-resistant nickel alloy that is laser cladded on the transfer rolls. Increased service life results from the special properties of the Colmonoy® 7331-60 alloy.

Steel Industry transfer rolls can be laser clad with Colmonoy® 7331-60, which has improved thermo-mechanical fatigue properties, meaning it is better at coping with cyclical heating up and cooling down, which can cause fatigue and failure in other metals. The perfect balance of hardness and ductility, Colmonoy® 7331-60 will soak up stress and reduce the potential for cracking. Packed with the maximum fraction of tungsten carbide, Colmonoy® 7331-60 gives tough support to hard metallics.

Any part exposed in service to abrasive wear is a natural application for Colmonoy®. New transfer rolls should be given a protective coating. Protected transfer rolls can also be renewed or refurbished by the same laser cladding process after extended periods of service thus avoiding the costly purchase of new units. This results in:

Any part exposed in service to abrasive wear is a natural application for Colmonoy®. New transfer rolls should be given a protective coating. Protected transfer rolls can also be renewed or refurbished by the same laser cladding process after extended periods of service thus avoiding the costly purchase of new units. This results in:

- Fewer replacement transfer rolls needed

- Less labor required to install them

- Less down-time

- Smooth enough to go directly into service - no machining or grinding needed

Colmonoy® has been used in the steel industry since our beginnings in the 1930s. Colmonoy® alloys have proved their ability to generate savings in the steel industry and a wide variety of other applications.

Achieve longer life for your rolls.

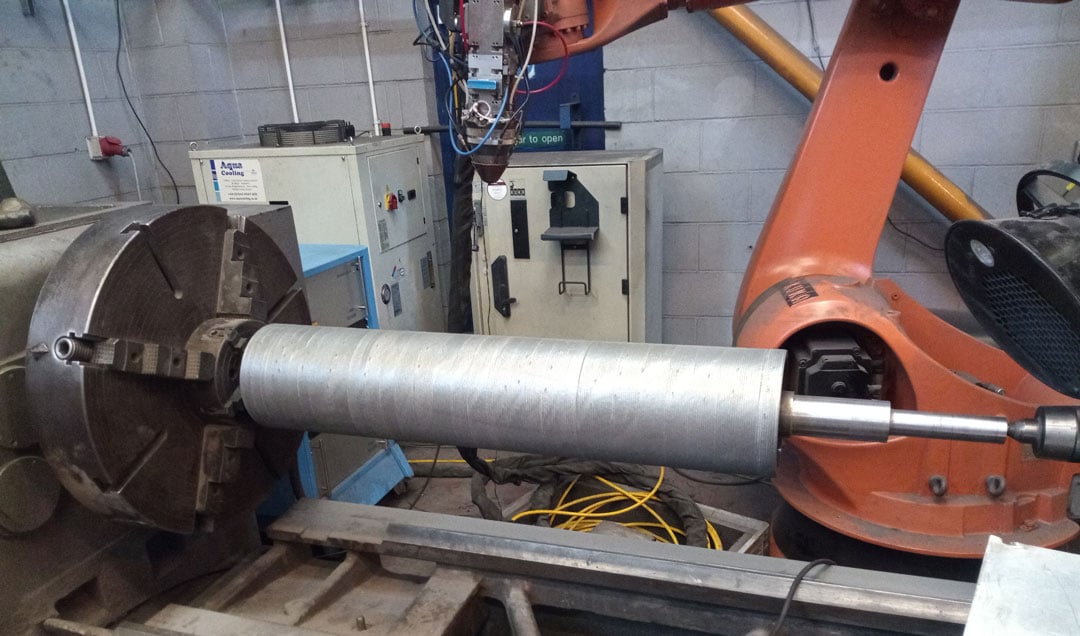

Transfer roll for the Steel Industry being prepared on spindle

Smooth finish on completed Colmonoy® 7331-60 laser cladded transfer rolls